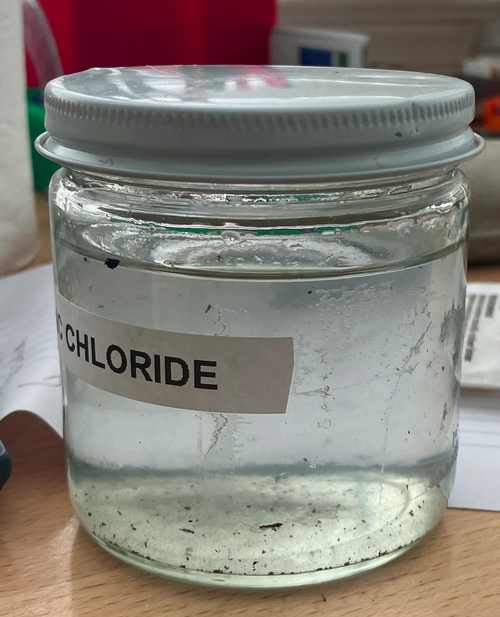

A common flux in soldering is zinc chloride solution. It is supposedly quite effective, though its corrosiveness makes it unsuitable for electronics. I tried using it as a tip cleaner for soldering irons that had oxidized to the point where they couldn’t be tinned with rosin-core solder.

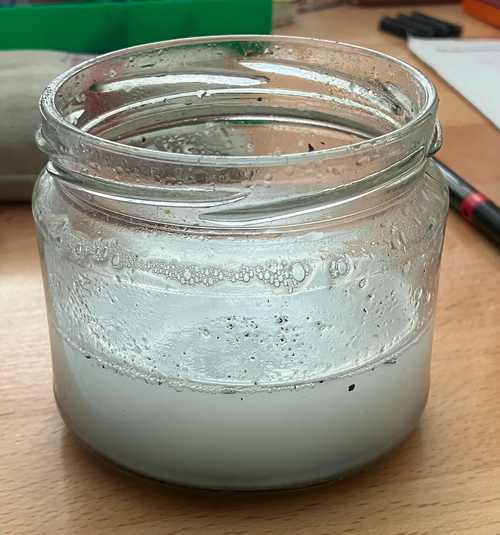

Zinc chloride (ZnCl2) is easy to make by yourself by dissolving zinc (Zn) in a jar of muriatic acid (HCl, 10M). The reaction was very vigorous for the first few minutes; the glass jar got noticeably warm, and steam came out of the jar. After a few hours I could still hold my ear up to the solution and hear some fizzing, so thinking that the reaction hadn’t completed, I left the zinc in the solution for a few days, but the solution just turned cloudy. This was probably due to the zinc corroding in water to form basic zinc carbonate (Zn5(OH)6(CO3)2), which reacted with with the zinc chloride to form a precipitate (maybe a suspension?) of zinc chloride hydroxide (Zn5(OH)8Cl2·H2O), also known as “basic zinc chloride”. More muriatic acid was added to dissolve the zinc chloride hydroxide and eliminate the cloudiness.

Previously, I’d tried to use various DIY methods to tin soldering tips, without success. This time, by alternately wiping the hot soldering iron in a small puddle of zinc chloride and applying solder, I was able to successfully tin an oxidized soldering iron. (The results in the featured image don’t look very impressive, but I assure you I got the solder to stick to the tip where it previously could not.) Apparently, according to various online sources, this works because the zinc chloride reacts with metal oxides to form a soluble oxychloride, or maybe because it thermally decomposes to make hydrochloric acid (and zinc oxide), which also dissolves metal oxides. I’m not entirely sure how this works.