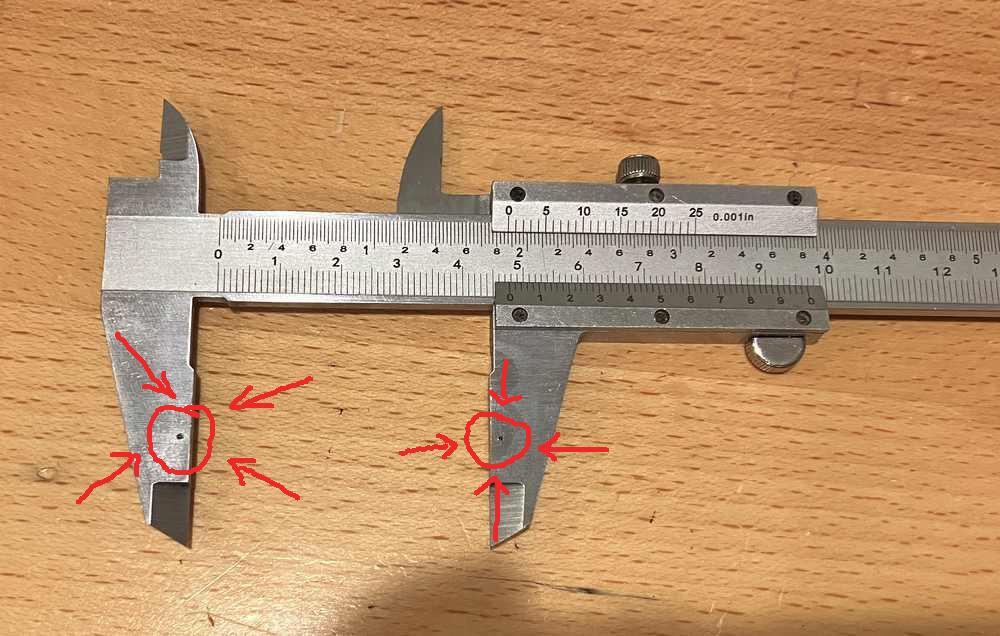

“The Vernier Caliper… may be used for accurate settings of dividers and trammels. Near the zero mark on the beam is a tiny indentation in the center of a small circle, and on the sliding jaw is another small cone-shaped mark. Set the vernier to the dimension required and then adjust the points of the dividers or trammels, by “feel” or with the aid of an eyeglass, exactly in the two marks.”

— Machine Tool Operation, Part I, Fourth Edition, by Burghardt and Axelrod

Unfortunately, not many vernier calipers today retain this feature, since the manual lay-out (i.e. scribing the locations of features on a part to serve as a guide for machining) that dividers and trammels are used for has become practically obsolete after the introduction digital readouts on machine tools. However, for the hobbyist who does not have access such machines, using traditional layout techniques is a good option for getting comparable precision. Sometimes a ruler and a marker just isn’t good enough. To put this feature on my pair of calipers, I put two small divots on the outside measurement jaws, perfectly in line with each other, 1/8″ apart.

First, I colored in the jaws with permanent marker to emulate the function of layout dye. Then, I separated the jaws a bit, and used a combination square put against one of the open jaws to scribe a line on that both jaws. When the they were brought back together, the lines matched up (almost) exactly. The scriber was made from one of those small promotional screwdrivers, which I forged, heat-treated, and ground to a sharp point.

with one hand and scribing the line with the other

To actually put the divots in the caliper jaws, I first tried to make my own prick punch. I’d previously been gifted a bag of broken tools from my school’s machine shop, so I took a carbide-tipped boring bar with a 1/2″ shank, cut the tip off, and ground a sharp point (~60°) on it. Based on the appearance of the sparks, I think it was a medium-carbon steel of some sort, with a carbon content somewhere between a file, and a piece of structural steel. To heat-treat it, I heated the tip red-hot with a propane burner, then quenched it in water. When I ran a file over the tip, it skated off, indicated that it was quite hard. I decided not to temper the punch, seeing as it was (probably) medium-carbon and I wanted it to be as hard as possible. Unfortunately, the prick punch made no impression at all on the calipers, which were probably some hardened martensitic stainless steel.

I next decided to use a pointed carbide burr made for rotary tools. The burr was put in a drill press set to its maximum speed of 3100 RPM. Using pieces of wood, I supported the calipers on the table, and drilled a divot on the scribed line, about 1/16″ from the edge of the solid jaw.

blunted from attempting to punch

into the caliper jaw

To determine the location of the next divot, I moved the calipers to the 1″ setting, set a pair of dividers to 1-1/8″ using a precise steel rule, and scribed an arc on the movable jaw by putting one leg in divot I’d previously made, effectively measuring out a distance of 1/8″ between the divots with the jaws closed. The reason I didn’t put just shut the caliper and and set the dividers at 1/8″ is that the divider legs get a little “wobbly” when set at small measurements, and do not maintain an precise distance between points.

I did my best to drill the next divot at the exact intersection of the line and the arc. Usually, it is possible to use the scribed groove to locate a punch by feel, but in this case, the scriber only scratched away some of the marker ink and made no groove, so I had center the carbide burr by eyeballing it. In the end, it was visually clear that the divots aren’t exactly horizontal with each other, but even assuming a vertical difference of 1/64″, this will cause a maximum deviation of √(0.125″2 + 0.016″2) – 0.125″ = 0.001″ (0.03 mm) from the horizontal measurement. I was able to check the spacing of the divots by setting the dividers to some distance, and then checking it against a steel rule by seeing if the points would perfectly enter the tick marks; they did.