This is the disassembly of a Yale Assure Smart Lock.

The outside part (called, according to Yale, the “Touchscreen Escutcheon”) basically consists of a touchscreen interface and a traditional cylinder lock. A metal plate with a keyhole mounting hole (that’s the hole shaped like a keyhole; it has nothing to do with keys), which is possibly an alternative method of mounting the lock, covers the screen mounting bracket. After it is removed, the screws holding the plastic bracket that holds the touchscreen can be undone. Another plastic piece holds the screen cable in place, and a metal bracket secures the small speaker, which is further held by some tape that needs to be unstuck. The speaker and screen cable are both connected to the screen via removable connectors, but these connectors have been permanently potted in place and threaded through a hole in the screen mounting bracket, so both the cable and speaker need to be removed before removing the screen.

The lock cylinder is a normal key-in-lever cylinder, but it’s mounted in a die-cast housing that clips into the main body of the lock. I suspect this allows for some inaccuracy when mounting the lock as there can be some play between the cylinder and touchscreen escutcheon. When the lock is mounted onto the door, two large screws connect the inside part of the lock with the die-cast housing through its two large holes, aligning the cylinder with the inside part of the lock.

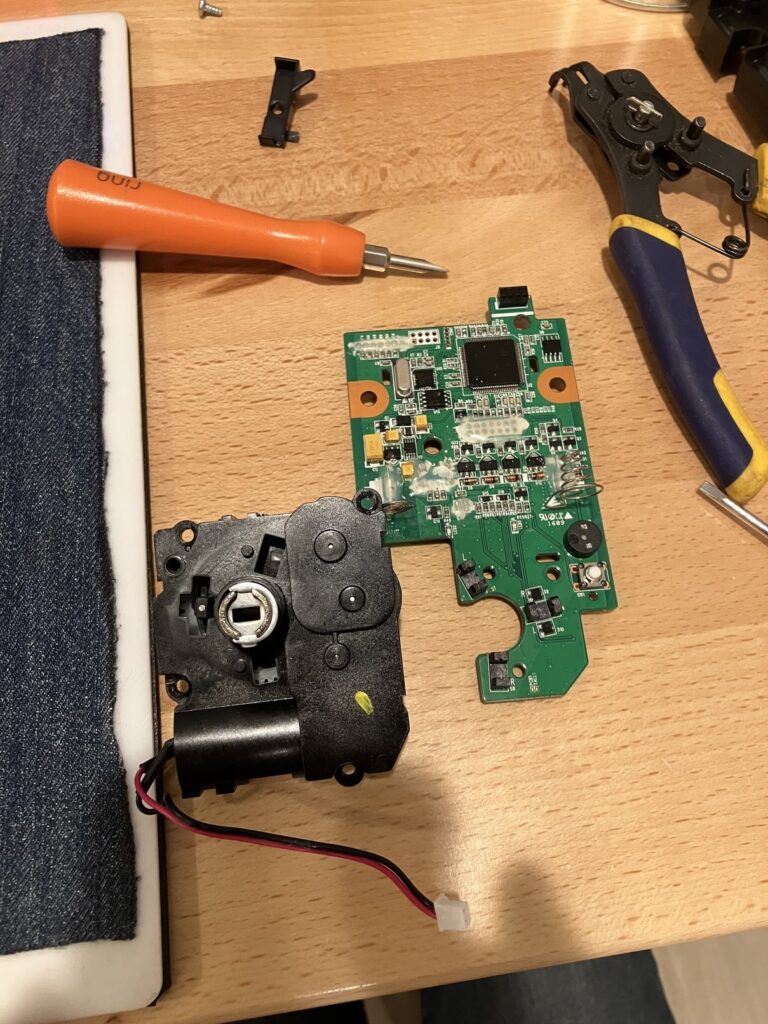

The inside part of the lock (the “Interior Escutcheon”) basically has four parts: the die-cast body, a circuit board, a battery holder, and the motor assembly. It is held together with two types of screws: a slightly shorter one with a wider head, and a longer one with a narrower head. The circuit board is held to the back of the battery case with two short screws at the top left and middle right and one long one at the bottom left, which also holds the cable bracket in place. After the circuit board is removed, the motor assembly can be removed by undoing 4 long screws, and then the battery case can be removed with just one.

The thumb-turn is fixed to the lock body with a simple exterior circlip. The thumb-turn has a small ball-bearing and a spring that pushes it against the lock body, which has two small divots that make the lock “click” in place when locked. The thumb-turn also has a protrusion (it’s not really visible in the picture, but it’s there) that slides in a slot in the lock face and prevents it from turning more than 180 degrees.

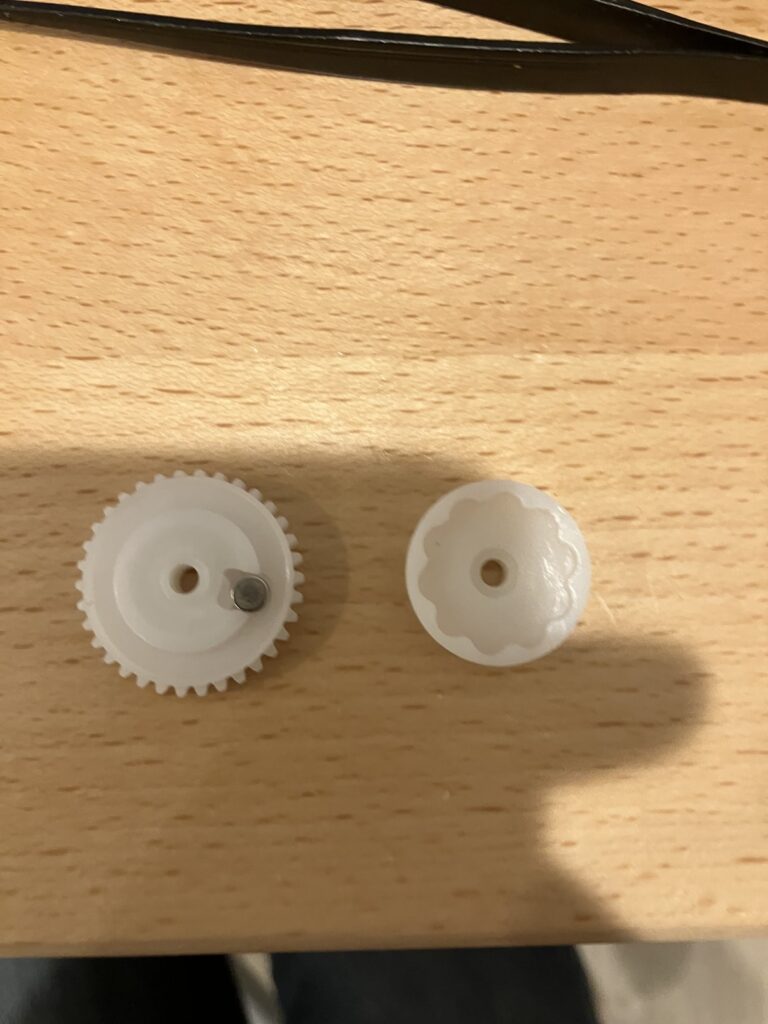

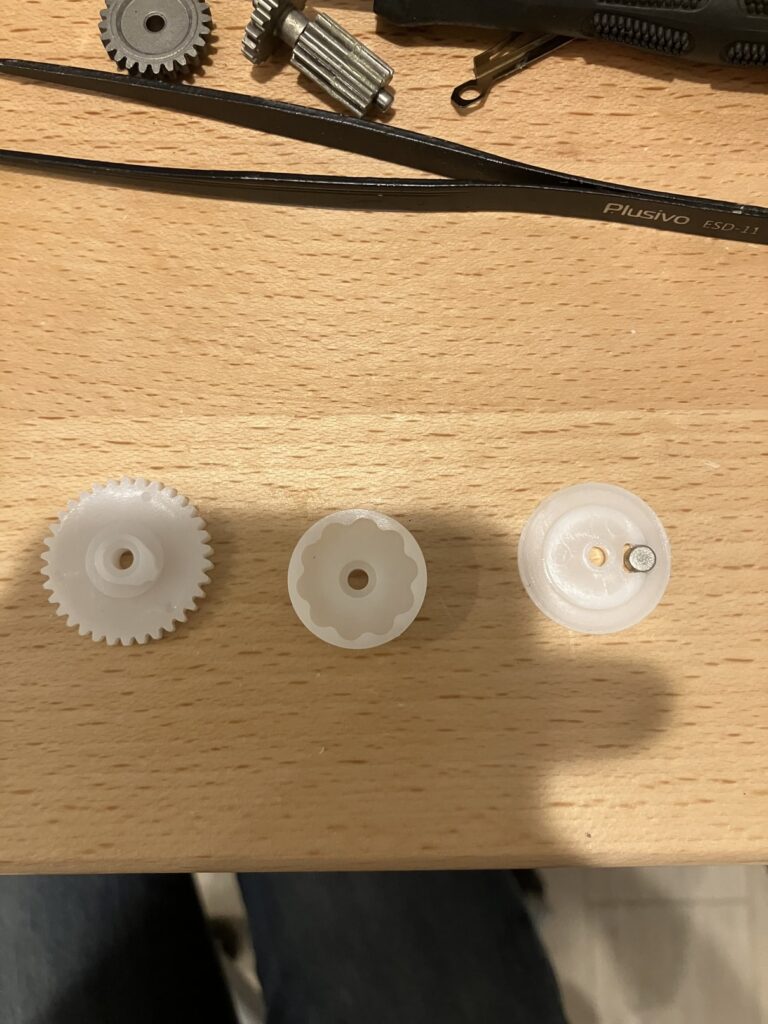

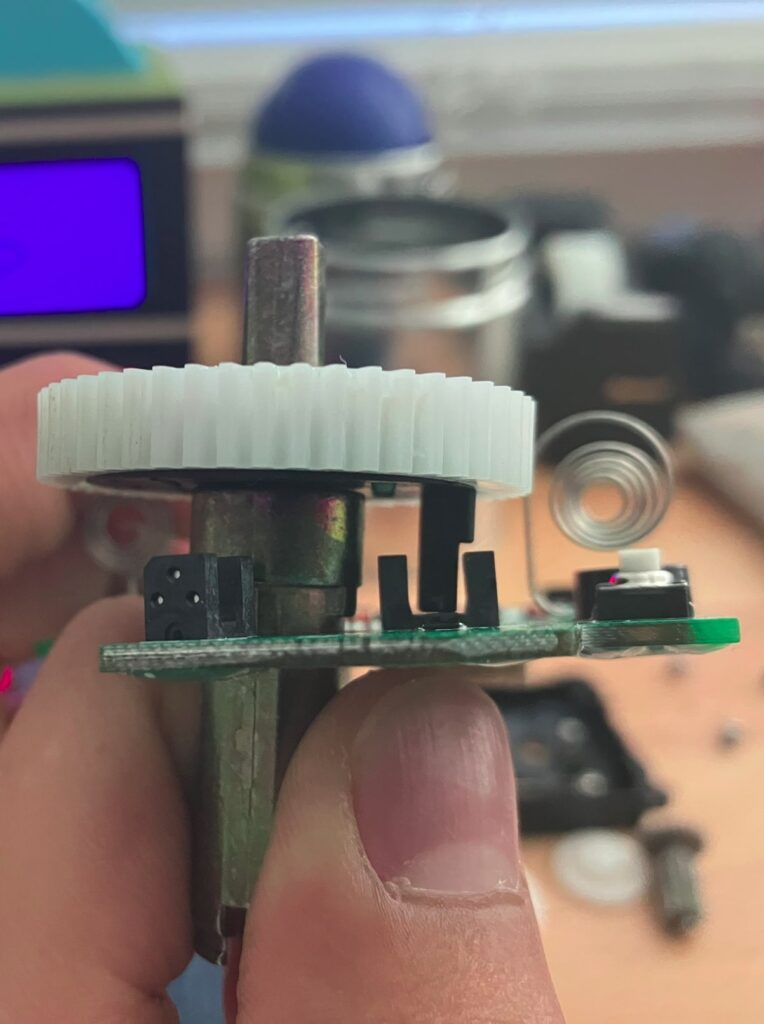

The motor assembly is held together with a few plastic clips along the edge of its body. essentially consists of a DC motor driving the lock through a worm gear and further reduction gearing. The medium-sized plastic gear has a mechanism that allows the lock to turn independently of the motor while allowing the motor to turn the lock. It actually consists of three layers: the bottom has a cam in the middle that pushes a small metal disc held in place by the middle piece outwards against the top piece, which has several indentations that the magnet can go into, thus locking the bottom and top halves together. When the motor is not rotating, the metal disc, which is actually a magnet, is attracted inwards to the gear’s steel shaft, and disengages the top and bottom halves.

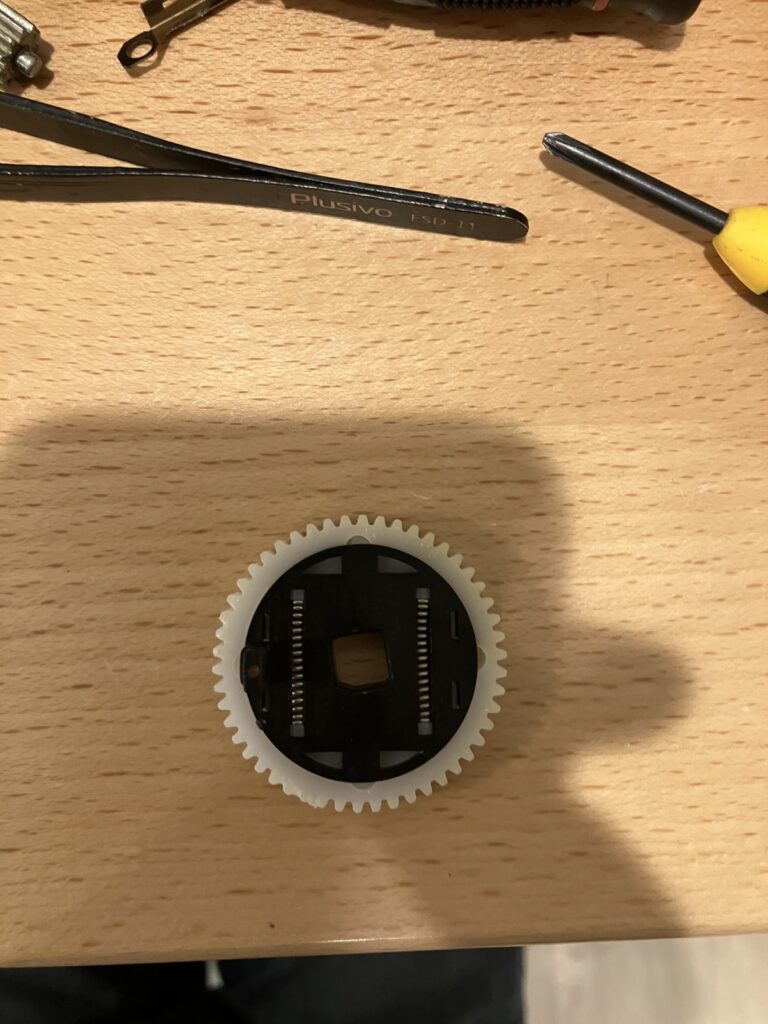

The large plastic gear in the middle has two important parts: firstly, the black plastic part in the center has two semicircular projections that catch similarly shaped indentations on the inside of the gear. The projections are thrust outward by two springs, and when the torque on the gear is great enough (for example, when the lock becomes jammed), the projects are pushed inward and allow the gear to slip, preventing damage to the motor. The center part also has a magnet that is detected by three hall-effect sensors on the circuit board, allowing it to sense the lock’s position. When fully assembled, the motor assembly has holes that allow these sensors to poke in.

I’m not going to go over how the lock is installed because you can read about it in its instruction manual, available here. I do have one thing to note though: the company Yale has been making locks since 1868, but it has only recently gone into the field of electronics. As such, the electronics are somewhat less robust than the mechanical components and care must be taken not to pull on the wires too hard or something like that.