This Fixit Clinic was held in the Hayward Public Library from 11:00 to 2:00 PM.

I took on the unwise challenge of attempting to repair a person’s VHS VCR, a task probably best left to someone older with direct experience with these devices. Luckily, I had watched a few YouTube videos on the subject so things weren’t as bad as they could have been.

First, given that the year is 2024, let me put a brief explanation of how VCRs work, taken from pages 260-261 of The Way Things Work, a wonderful book that you should read.

Like a television receiver, a video recorder first extracts the video (picture) signal from the television carrier signal that is either broadcast or cabled to the home. But instead of sending the video signal to the television tube to be seen, the video recorder preserves the signal on tape. It does this with a tape casette in much the same way that a tape recorder records a sound signal. The video signal goes to a record-replay head that records it on the magnetic tape, and replays the tape to send the recorded signal to a television set. However, the tape must pass the head at a very high speed to record a video signal, because so much information has to be stored. The head therefore rotates rapidly as the tape passes, reocrding video signals in diagonal tracks across the tape.

Loading The Tape

When the cassette is inserted into the recorder, the loading poles take the tape out of the cassette and move it into contact with the heads and rollers in the recorder.Rotating Video Heads

The Way Things Work by David Macaulay and Neil Ardley

The drum contains two video record/replay heads on opposite sides of the drum and is tilted relative to the tape. The pair of heads records one complete picture in each revolution in the form of a pair of diagnoal tracks across the tape.

Anyhow, the problem was thankfully not with any of the recording/replaying hardware but with the loading and unloading. For some reason, the recorder was unable to rewind the tape into the cassette and subsequently unable to eject it. (It would be a disaster if a VCR tried to eject a tape still wrapped around the video head.)

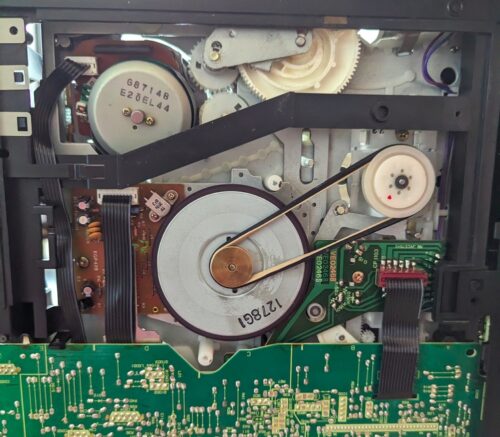

We observed that the two tape spindles were driven by the same motor: a pivoting arm transmitted rotary motion through some gears to one spindle, rotating the corresponding spool while the other spool was allowed to spin freely with some friction to keep the tape taut. The mechanism was designed so that the tape would always be pulled, for example during normal operation the take-up spool would pull the tape through the transport from the feed spool. When the motor spun in the opposite direction, its torque was supposed to pull the pivoting arm in the other direction, engaging the other spindle to pull the tape in the other direction.

However, this failed to happen; upon pressing the rewind button, the pivoting arm failed to swing back and the takeup spool would turn in reverse, spitting out a bunch of tape and making a mess. We attempted to reinforce the crumbling square belt that drove the spindle with a thin rubber band (a bad idea since belts are meant to transfer motion precisely, but rubber bands are springy and imprecise) to no avail. Also, we tried lubricating several components with the idea that they were causing the pivot arm to stick. However, we observed that the pivot arm worked properly with no tape loaded, and also that by turning the spindle motor by hand, it was possible to rewind the tape into the cassette, allowing it to be ejected.

In the end, we were unable to fix the VCR due to time constraints and the owner decided to take it to a repair shop. He curiously noted that he had previously called many shops claiming on their storefronts to repair VCRs, but that those advertisements were outdated and most places no longer serviced them. If a legitimate repair shop failed, he said, he would “drive a wooden stake through its heart and bury it at a crossroads”.