I made a gyroscope. Part of that involved casting 12 zinc weights to go around the rim of its rotor, which gave me a lot of practice ramming and pouring molds, and I learned a lot.

Firstly, for my extremely rudimentary dirt-bonded sand, the right moisture level is just enough to turn the sand noticeably dark, indicating that the clay is fully wetted with water, but not so much that it sticks to the rammer. While many hobbyists on the internet recommended using a peen-shaped rammer to better compact the sand, I found it easier to simply ram the mold in layers. Furthermore, despite recommendations to not ram the sand too hard, my pine wood rammer wasn’t anywhere near heavy enough to do that — even when ramming with all my strength, there were no issues with venting, possibly also due to the coarseness of my sand.

Secondly, I got much better at pattern removal. After trying to pull them out with duct tape and just digging them out with fingernails, the best method turned out to be the most commonly used, which is drilling some holes and pulling them out with wood screws (with their tips cut off). Also, I found that a good way of applying corn starch as a release agent in a very thin layer (so that it doesn’t cause burn marks on the castings) is to saturate a paintbrush with it, tap off the excess, and then hold the bristles over the part while tapping the handle on the rim of the flask. Next, given the sand’s tendency to get under the mold and cause sand tear-out, it was often helpful to scrape it out from underneath before ramming the cope. Additionally, it was definitely necessary to tap the patterns with a screwdriver handle before removing them; a good gauge for if you’ve tapped enough is to put your finger on the pattern while tapping, and if you can feel it move a bit, then it’s already loose.

Here are some miscellaneous things:

- There wasn’t really a need for vents. The cavity found on the top side of the casting (the back side of the part) seems to be caused by shrinkage, not improper venting.

- I suspect that metal leaking out of the mold was caused by the cope and drag not seating properly, rather than over-crumbly sand (though this may still be a factor) as I previously suspected.

For the first time, I tried using one of the more common sources of zinc for hobbyist casting: wheel weights. Unfortunately, the 14 kg bag of weights I got from a local tire center was only 23% zinc, the rest were iron, rubber, random trash, and a few lead weights (which are very important to sort out since they can cause zinc pest in castings). Of that 23%, 10–20% was probably lost in the form of slag and the steel clips used to attach the weights to the wheels.

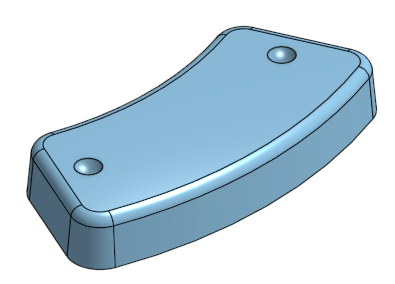

Finally, here are some pictures of the whole process.

One response to “Casting Weights for a Gyroscope”

[…] The repetition involved gave me a lot of chances to practice and feedback with ramming molds. There’s a whole blog post about that here. […]