This event occurred at the Hacker Dojo in Mountain View, a collaborative hackerspace for software projects.

I first worked on a portable electric radiator with a detached cord winder (the plastic thing you wind the cord around for storage), a loose caster, and a plug with burn marks. The cord winder had a cantilever snap-fit that was bent back so it wouldn’t clip properly. I used a heat gun and file to bend and shape it back into place so it could be reinstalled. The plug’s burn marks were most likely due to arcing from an improper connection, and we replaced it with one of those hardware-store ones you can quickly install on any wire.

The caster was of the office chair type (forkless) with its stem riveted to the radiator’s sheet metal legs (like these). The wheel had been pushed up through the leg such that the flange designed to keep this from happening had deformed the hole in the sheet metal. Since we could not push the flange back under the hole, we simply filed it off and used a hose clamp to replace it, creating a slightly wobbly but perfectly functional solution.

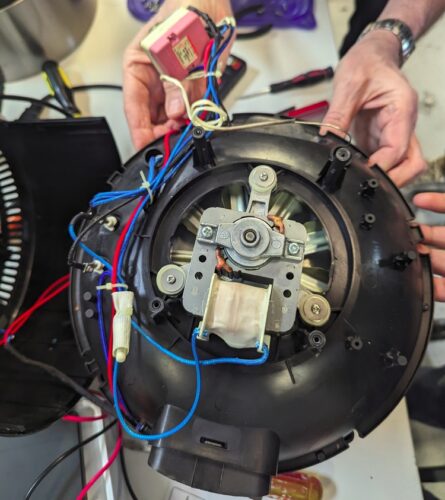

Additionally, I worked on a Krups EY-201 air fryer. The thermal fuse was blown, most likely from a blocked exhaust vent causing it to overheat, but also possibly due to some electrical failure which we did not observe. Replacing it required almost complete disassembly which was difficult, as in most kitchen appliances. In contrast to coffee machines, this air fryer used screws to hold most parts together — on the one hand, that meant easier disassembly, on the other we needed to keep track of which screws went where. One important thing to note is that the vent cover had to be removed in order to remove the top assembly.

The circuit was about as simple as it gets, with the safety switch, timer, and thermostat wired in series to provide power to the fan, heating coil, and indicator lamps. Since the thermal fuse was wired last, we could use a non-contact tester to confirm that the components connected the fan and heating coil to line power but the thermal fuse broke the neutral connection.

One tool I found very useful in both these repairs was a digital power meter that measures the amount of power consumed by an appliance. (You may know it under the brand name “Kill-a-Watt”.) It enabled us to see if everything was functioning properly and not just lighting up.