This Repair Café was held at the Museum of American Heritage.

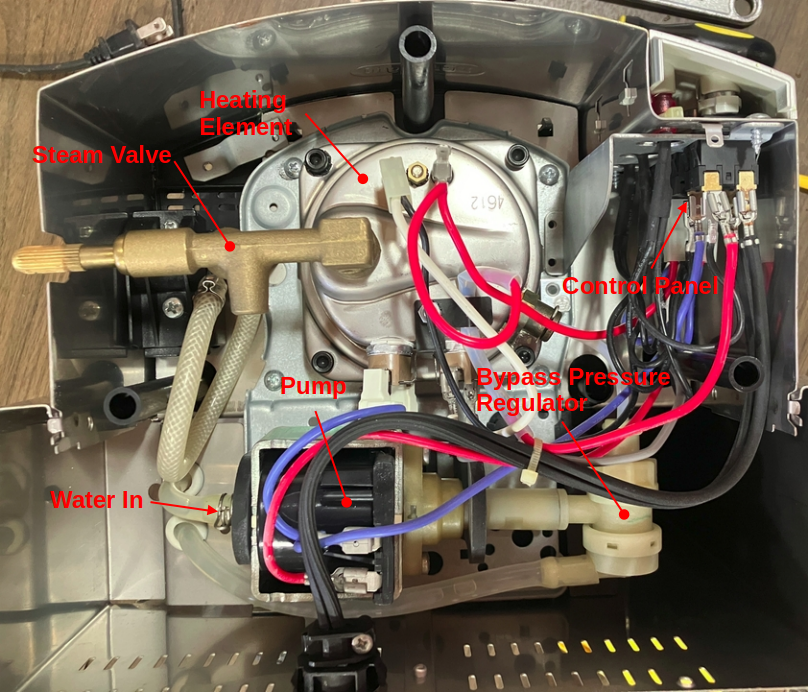

First, there was a DeLonghi EC702 espresso machine that wasn’t providing sufficient pressure to push the water through the coffee grounds. Unfortunately, the owner forgotten to bring the portafilter (filter basket), so we couldn’t confirm this; running the machine without the filter in place resulted in very slow water flow. Anyhow, his research led him to conclude that the pump was faulty; he wasn’t able to replace it himself because he didn’t have the proper screwdriver to remove the Torx security screws. We replaced the pump and found that it increased water flow (without the filter in place) slightly, and the owner concluded that it’d likely been fixed.

I suppose that since it’s a coffee maker of some sort, I must comment on its take-apartability. Aside from having security Torx screws, I’d say that this one was pretty repairable, since everything was held together with a few screws in mostly accessible and logical locations, and all components were placed in an easily accessible manner. The rubber hoses on the pump did require some persuasion with a heat gun to get off, though.

Additionally, someone brought a waffle iron “old enough to be made in the USA” that had mysteriously stopped working that morning. It turned out that the cord was broken, most likely due to the strain relief issues caused by its insulation having turned to jelly with all the oil it was exposed to. Removing the base cover revealed the base was also completely soaked in grease. Thankfully, replacing the cord was a simple matter of unhooking the old one through some spade terminals, crimping connectors onto a new cord, and installing it.

Someone also brought in two electric chainsaws: a plug-in with the chain improperly tensioned; and a cheap handheld, battery-powered one that wouldn’t run. Having no experience with chainsaws, I re-installed the chain on the first to the best of my ability and found that it “cut air” just fine. For the second, the owner was using an improper power supply to charge the batteries, which were completely dead. We tested the chainsaw using a power supply set to 24 V (my best guess based on a quick internet search of the chainsaw’s intended voltage), but the starting current draw was too much for the 5 A power supply, and the chainsaw often failed to start, even after lubricating the chain and reducing its tension.

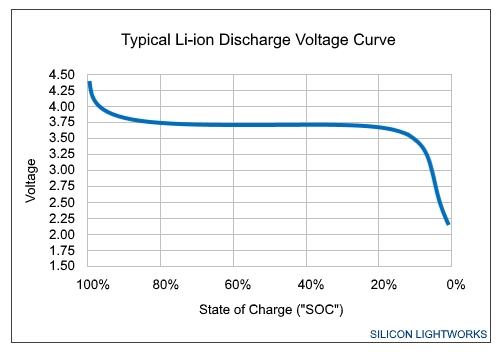

Here’s what I learned in hindsight: The battery consisted of 5 lithium-ion cells, marked as producing 3.7 V, wired in series. Since lithium-ion batteries actually produce about 3.6 V when in operation, the battery pack should have a voltage of about 18 V. However, such packs are often marketed as 21 V since a fully-charged lithium battery has a voltage of 4.2 V, which quickly falls off as the battery discharges. Also, since lithium-ion batteries can produce great instantaneous voltage, so the battery pack would likely have less trouble running the saw than the power supply.