This Repair Café occurred at the Central Park Library in Santa Clara.

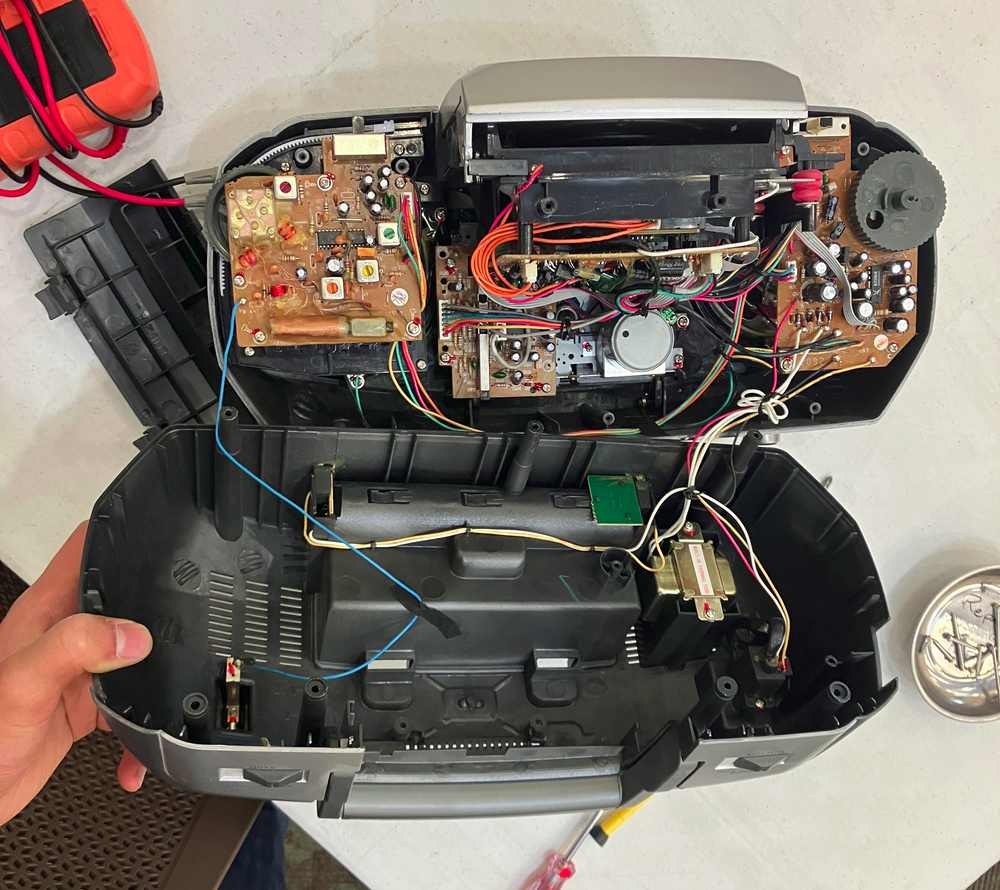

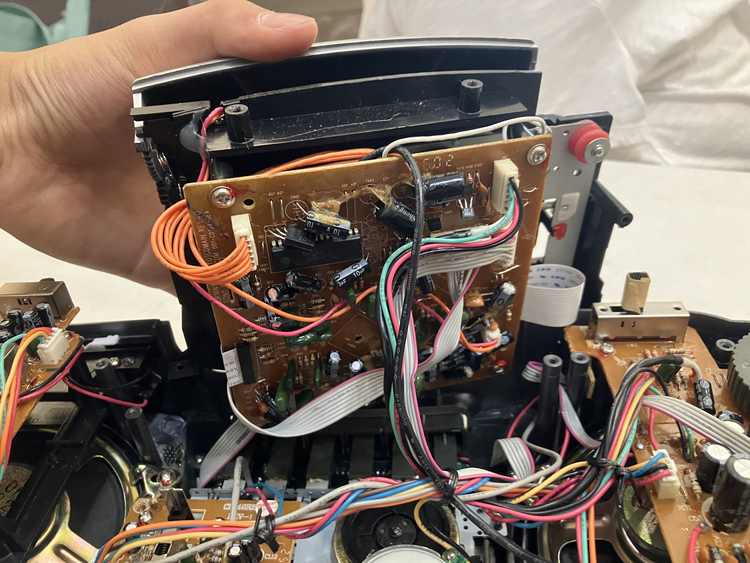

The first thing I worked on was a boom box from the 2000’s where the cassette player was playing very slowly and softly. As suspected, the belts inside were very loose, causing the capstans to turn slower than normal. There were no replacement belts available, and we couldn’t find an o-ring that fit either. The owner declined to purchase replacement belts online. At any rate, we found that replacing the belts would have meant a considerably involved disassembly, so the owner decided to abandon the tape deck and just use the boom box for its CD-playing ability.

Someone else brought in an articulated lamp where one joint was loose. As it turned out, the hinge pin had broken out of its plastic mounting, probably due to the repeated high-torque loads applied by the friction pin. (I am disinclined to think the owner dropped it but didn’t admit it because she was honest about dropping another item she brought to be fixed, a Kindle.) I attempted to glue the mounting back together with Gorilla Glue, but seriously doubt that it worked. The owner said she wanted to repair the lamp because it was an expensive air-filtering model, but I suspect it was a bit of a scam because it had a tiny fan incapable of moving any significant amount of air, and the air purification technology was an ionizer, which generally don’t work all that well.

As a final note, a press fit in thermoplastics is worrisome, substandard design. Replace it with snap fits or elastic fits — or risk creep and fractured parts

The Elements of Mechanical Design, by James G. Skakoon

An interesting thing I got to work on, that I’d never tried fixing before, was a microwave. Apparently the fuse had blown, the owner had replaced the fuse, it blew again, and then he replaced the microwave and put the old one in storage for a few years. The main safety precaution in working with such a high-voltage device was to discharge the capacitor. The microwave included an instruction manual, so I followed its troubleshooting flow chart (it looked a lot like this), verifying that the capacitor, interlock switches, and varistor worked. I tried checking the relay by measuring resistance across its terminals, and wasn’t sure how to check the transformer.

Interestingly, according to the troubleshooting manual, the interlock switches should have infinite resistance across the terminals when the door is open, but I measured a resistance of about 36 ohms. The manual mentioned the need to disconnect one lead of the switch to isolate it when checking the monitor switch (some other safety switch), but not with the interlock switch. That said, there were one or two typographical errors I noticed in the manual, so this may have been one of them.

After failing to diagnose anything, I tried following another flowchart, which suggested replacing the blown fuse and trying to operate the microwave. The owner had brought another fuse, part of the package of fuses he’d bought to replace the original blown one. As it turned out, that brand-new fuse was already dead, so we got another fuse of the same rating. After installing it, the microwave worked perfectly and was able to heat up a cup of water. My best guess for what happened is that the original package of fuses was defective, so nothing was ever really broken. I’m not sure why the fuse originally blew, but it may have been a one-off event. On the other hand, the owner (whose memory was quite fuzzy by his own account) seemed to recall that the microwave did function a few time when he installed the new fuse, before it eventually blew again.

The second flow-chart I tried suggested installing a “service breaker” in place of the fuse for resettable over-current protection. We didn’t have one, but it seems like a useful tool. I might try to make one, perhaps electronically-based to vary the trip current.