This Repair Café took place at the Saratoga Library. There seemed to be a lot of people.

The first item I received was a CD player/radio/speaker that wasn’t playing well. The CD player played very slowly and indistinctly, while the radio played only static. Listening to both through the headphone output produced the same effects. Suspecting that a loose belt might be at fault for the CD player (although the CD seemed to be spinning up alright), I decided to take it apart. However, all the wires and cables impeded removal of the circuit boards, which was required to get at the CD player, so the only thing I was able to do was move around the play head a bit. Another fixer also suggest unplugging and replugging some cables, which we did.

Funnily enough, after doing those two things, the CD player worked. I didn’t initially realize the long bundled-up wire sticking out of the case was a radio antenna, and since disassembly required that we un-wind it, the radio also worked much better.

Something else that I got was an old mechanical clock that wouldn’t, according to the owner. After winding it up fully (until resistance was felt), I couldn’t find anything wrong with it; the bells rang perfectly at each hour and half-hour, and the pendulum kept decent time. The owner said he’d only wound it a few turns; maybe this was why it wouldn’t run for him. He also suggested that I oil it, but given my previous experience with typewriters, and similar advice given by another volunteer, we decided against it.

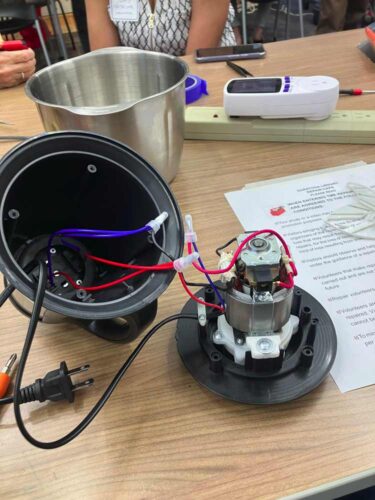

Finally, someone brought in a mini food processor, not unlike this one, with the motor mounted above the bowl. The owner explained that she was attempting to cut up some pork when the motor just gave a small twitch and then gave up; it had been used only once before to process shrimp. To me, this symptom suggested a blown thermal fuse, which might have resulted from the motor getting overloaded and heating up. On disassembly, it turned out the issue was insufficient contact between the universal motor’s commutator and its brushes, which had for some reason gotten jammed inside the little tubes they were supposed to slide freely in. After removing the rotor, I was able to push out the brushes and file them down a little to get them to slide better. One of the brush housings had also gotten cracked, possibly during the disassembly process (I was rapping on the motor to try to release the brushes, and might have hit the housing), so I glued it shut with some Loctite 2-part plastic bonder.