I realize that the field of hobbyist 3D printing is rapidly advancing and that this post may become obsolete very soon.

How I Got It

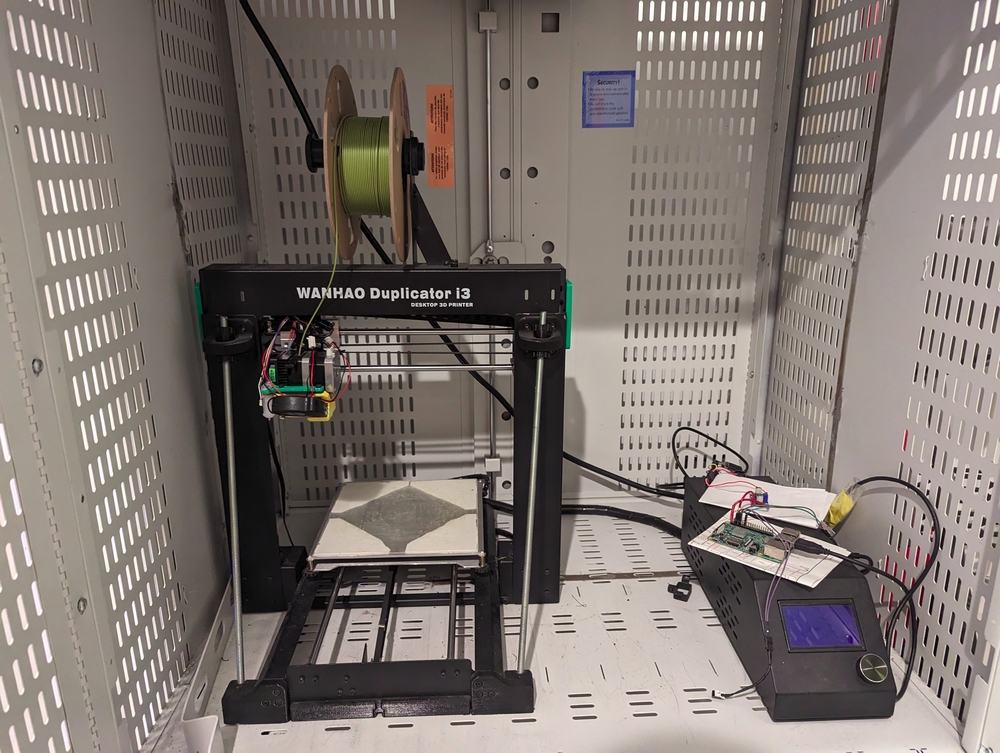

I got this printer used for $30 on Nextdoor in 2020. It was a Wanhao Duplicator i3 v2 that came with frame braces, a glass bed, and a Cobra Cooler fan duct. At the time I knew almost nothing about the details of 3D printing, only the theory, which can be summarized in the sentence “hot plastic extruded in layers to form an object”.

Upgrades

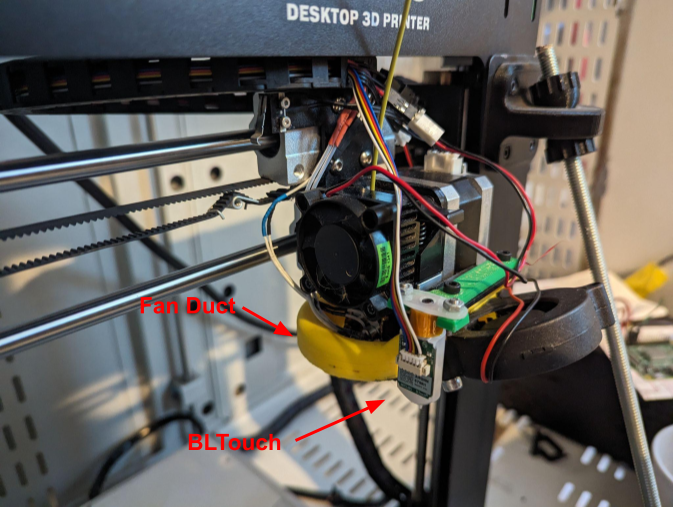

After seeing the first layer fail to go down many times despite having leveled the bed, I decided to install a BLTouch auto bed leveling system, a process that took a very long time with many complications. The most important thing I took away from this process was that a leveled bed does not necessarily improve first layer quality. In my case, increasing the first layer flow rate in the slicer was most important to improving print quality.

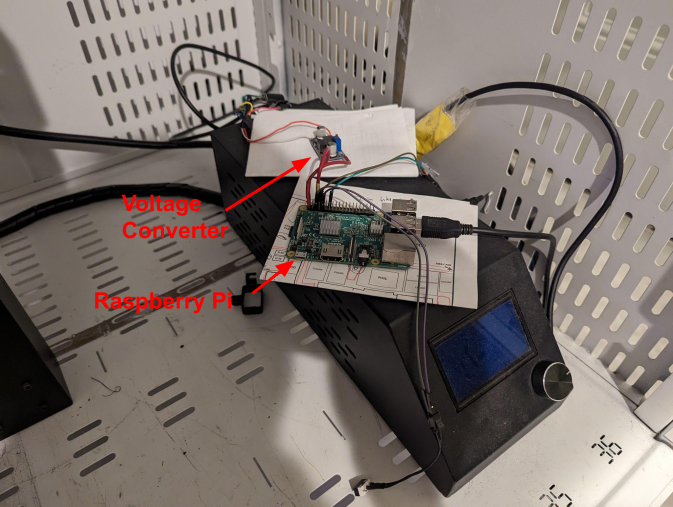

With a few Raspberry Pi’s left around from previous projects, I decided to add Octoprint to the printer, not only for its added convenience but also because it meant I could do away with the SD card slot and the space it took up in firmware. Installing it was a simple matter of connecting some wires to the 12V power supply and using an LM2596 buck converter to change that to 5V and power the Raspberry Pi.

The previous owner of my printer had installed a PLA Cobra Cooler fan duct and added masking tape around the air outlets to protect them from the heat of the hotend. Unfortunately, it snapped off because it was installed with superglue and I didn’t really want to glue it back on. Since most fan ducts require a working cooling fan to print (and anyway, I didn’t want to print a PLA fan duct), I went to my local makerspace and spent multiple weeks vying for a spot on their 3D printers to print a DIIICooler (link here) with PETG. It works very well and I have no complaints

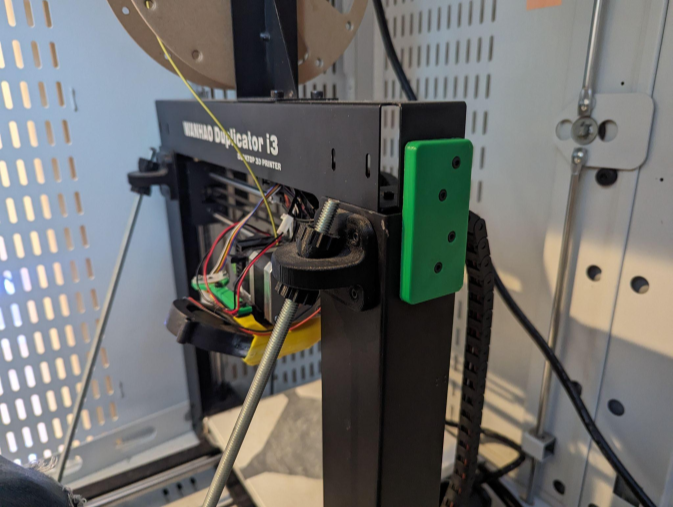

Although the Wanhao i3 technically has a 180mm Z-height, the top of the frame starts interfering with the extruder wires when raised to this height. I printed an upgrade I found online to solve this problem by raising the top of the frame slightly (link here).

Other Stuff

At some point (I assume this happens to everyone), I didn’t watch the first layer go down (cue rotten tomatoes) and the blob of death happened. For those who don’t know, it’s when the extruded layers stick to the nozzle and start building up into a bigger and bigger blob that causes significant damage. In my case, I was able to remove it with pliers and a heat gun and clean up the hotend with a wire brush. In removing it, the thermistor wire snapped and the thermistor had to be replaced.

I use regular glue sticks as a bed adhesive, which works fine — it sticks far too much for the first five or so prints, just enough for the next ten, then starts wearing down by the last five. I’ve tried printing on bare glass before but it didn’t work too well, possibly because the flow rate was too low.

An interesting project I did was printing some hooks to repair something and testing their strength. An open hook with a circular cross-section of diameter 5mm, printed in PLA held something like 20-30kg of weight (two or three bricks in a five-gallon bucket plus enough water to fill it) before snapping spectacularly. Unfortunately, that was still too weak for the intended application (A tripod dolly), so I used some copper wire twisted into a loop instead.

A General Impression of the Art

Given my experience, one cannot know about 3D printing unless they actually use and maintain one or are constantly exposed to 3D printers (NOT just 3D printing) in other ways. Although many wealthier schools may have a few 3D printers, they are really only used for printing name tags and trinkets, and (especially at the elementary and middle school levels) the teacher handles everything beyond 3D design.

I feel that much of the value in owning a 3D printer comes in owning a piece of machinery designed and improved by hobbyists that is by no means perfect. It’s just waiting to be improved or modified — tinkering with the printer is as much a part of 3D printing as the printing itself. It is for this reason I say that using a 3D printer and owning/maintaining one are two separate things. However, as printer design gets more and more refined, the capacity for improvement decreases. As well, manufacturers are starting to erect walls that somewhat discourage improvements and changes to their designs. Of course, the main reason companies do this is not to discourage innovation — it’s to prevent a slough of (“cheap Chinese”) companies from stealing the success of their product that they spent significant money and time developing by releasing a lower-priced, inferior product.

By the way, I’d like to address two common misconceptions about hobbyist 3D printing. The first is that 3D printers are useless pieces of junk that break down constantly and are used only to print trinkets. While it is true that many stock 3D printers are terrible and need upgrades to print more useful things, even a stock 3D printer can be useful in printing a huge variety of small, intricate plastic objects. This may not initially seem useful until you look around and see just how many small, intricate plastic objects exist in your life. Also, a bulky piece of plastic can be stronger than sheet metal, so 3D printing is not just limited to low-strength applications.

Another misconception is that 3D printers are low-cost miracle machines used to print not only plastics, but metals, cakes, and human organs. While it’s true that some printers are low-cost while others are attempting to print metals, cakes, and human organs, the two do not intersect. The fields of metal, cake, and organ 3D printing are still in their early stages, will probably not be used anytime soon (though metal 3D printing does show some promise in producing small intricate parts in one piece), and are certainly not low-cost.

One response to “3D Printer”

[…] the most time-consuming and educational part of building the speedometer was 3D-printing the case since it was the first time I’d used the printer for anything practical. After lots […]