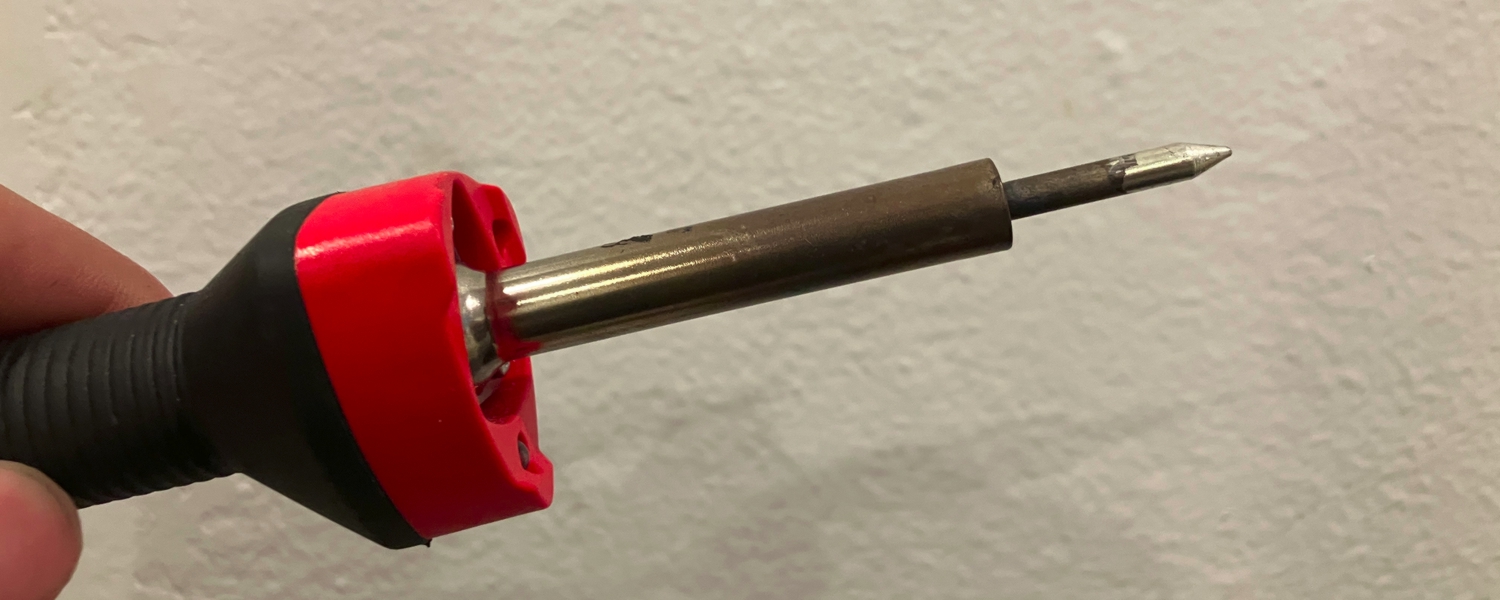

Soldering iron tips are made of copper plated with a very thin layer of iron. Unfortunately, this plating can oxidize if you don’t clean and “tin” it (that is, coat it with solder to protect it), and this can be very annoying because the oxidation is difficult to get off and prevents the solder from wetting the tip.

There are a number of ways to get stubborn oxidation off. The recommended way is use some sort of tinning compound designed especially for this purpose, like sal ammoniac.

Over the years, I’ve tried a few alternative methods, mostly without success.

- First is just ignoring it. This works surprisingly well it you’re just doing THT soldering. Unfortunately, the oxide layer slowly flakes off, exposing the copper core, which rapidly dissolves into the solder.

- I’ve also tried two lemon juice-based methods. The first is to soak the tip in lemon juice for a while, which has no effect on the oxide. The second is to heat the tip up and plunge it into the juice, which just leaves a lot of carbon.

- Seeing that citric acid can be used as a tip cleaner, I tried boiling down some lemon juice (from Meyer lemons), but just ended up with a very sour sugar syrup clearly unsuited for tinning. It makes a pretty decent sour candy, though.

- Paste flux for soldering copper pipes also just leaves lots of carbon.

- Electrolytic rust removal (running an electrolytic cell with the tip as the cathode) and vinegar each removed the bulk of the oxide, but still left a thin layer of oxide that made the surface impossible to tin.

- Although this is not recommended, and probably for good reason, stainless steel wool scrubbing pads were also effective at getting off most oxidation. They still left the tip impossible to tin. I’d assume they’re less aggressive than normal steel wool simply because the strands are larger and smoother, though they can probably still erode away the iron if used too much

- Finally, I tried using a galvanic single-replacement reaction to reduce the iron oxide by oxidizing zinc, placing the tip in brine in contact with bits of zinc, but this didn’t work.

After trying all this, I realized that I had a tinning flux all along in the form of some Stay-Clean® liquid flux I bought for a science project two years ago for the purpose of soldering stainless steel. It’s made of ammonium chloride (sal ammoniac), zinc (I interpret this to mean zinc chloride), and HCl. I just poured some into a sauce dish and dipped the iron in, then plunged the tip into a large blob of molten solder, repeating the process several times to completely tin the tip, and wiping off the iron on a wet sponge in between.

As you can see, removing oxidation from soldering tips is difficult if you don’t have the proper materials. So tin your soldering tips, and you won’t have to go through this unpleasantness.

One response to “(Failing To) Clean Soldering Tips”

[…] I’d tried to use various DIY methods to tin soldering tips, without success. This time, by alternately wiping the hot soldering iron in […]