Category: Random Projects

Random projects that I do to improve my life, try out an interesting new technology, learn a new skill, etc.

-

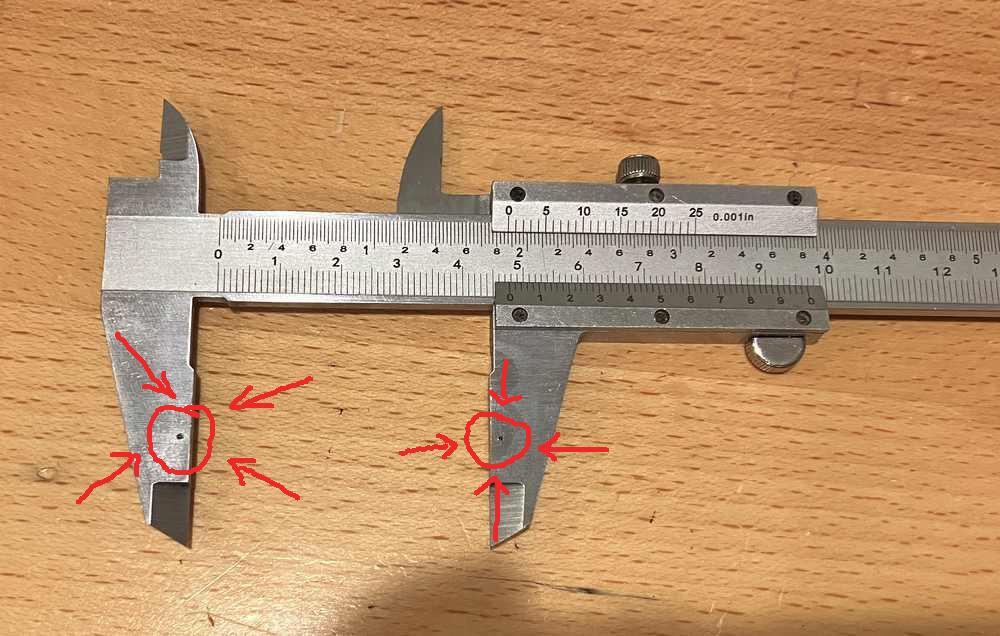

“The Vernier Caliper… may be used for accurate settings of dividers and trammels. Near the zero mark on the beam is a tiny indentation in the center of a small circle, and on the sliding jaw is another small cone-shaped mark. Set the vernier to the dimension required and then adjust the points of the dividers or trammels, by “feel” or with the aid of an eyeglass, exactly in the two marks.” — Machine Tool Operation, Part I, Fourth Edition, by Burghardt and Axelrod Unfortunately, not many vernier calipers today retain this feature, since the manual lay-out (i.e. scribing …

-

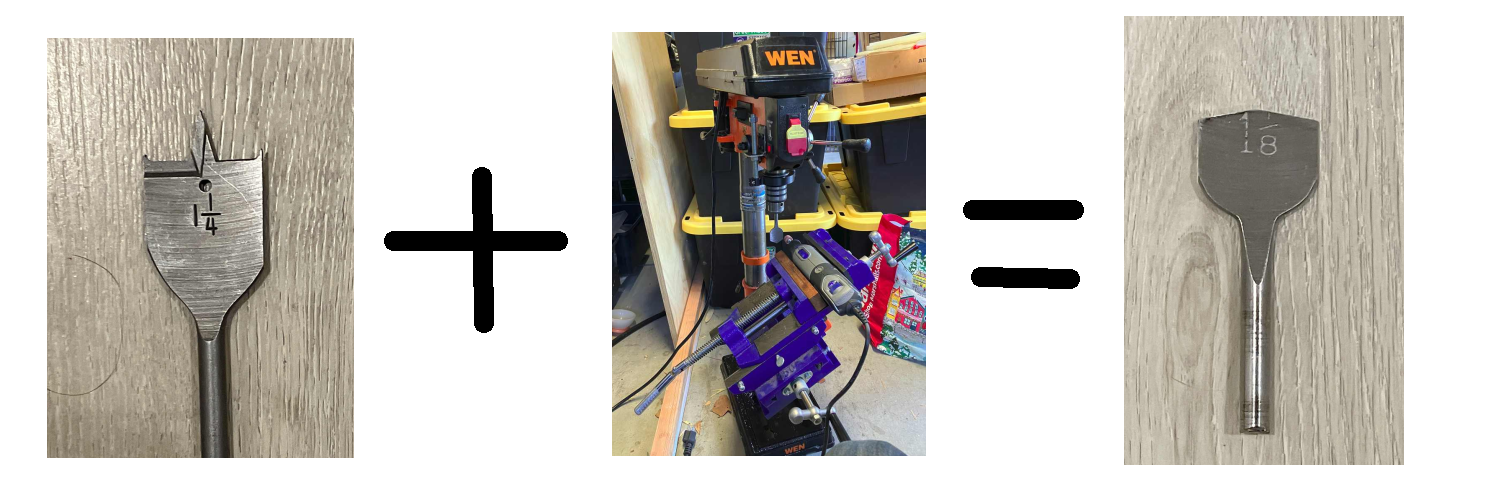

I previously used my drill press as a strength tester. Now, with two modifications, it can grind spade drills! Modifications This tool grinder works by mounting a Dremel rotary tool in a cross slide vise and a tool in the drill chuck. Column Extension In some cases, tilting the table (discussed later) caused the original column height to be inadequate after mounting the cross slide vise and Dremel. Looking online I saw that people recommended extending the column with a length of automotive tail-pipe, so I measured my column, and quite luckily found a pipe at my local auto …

-

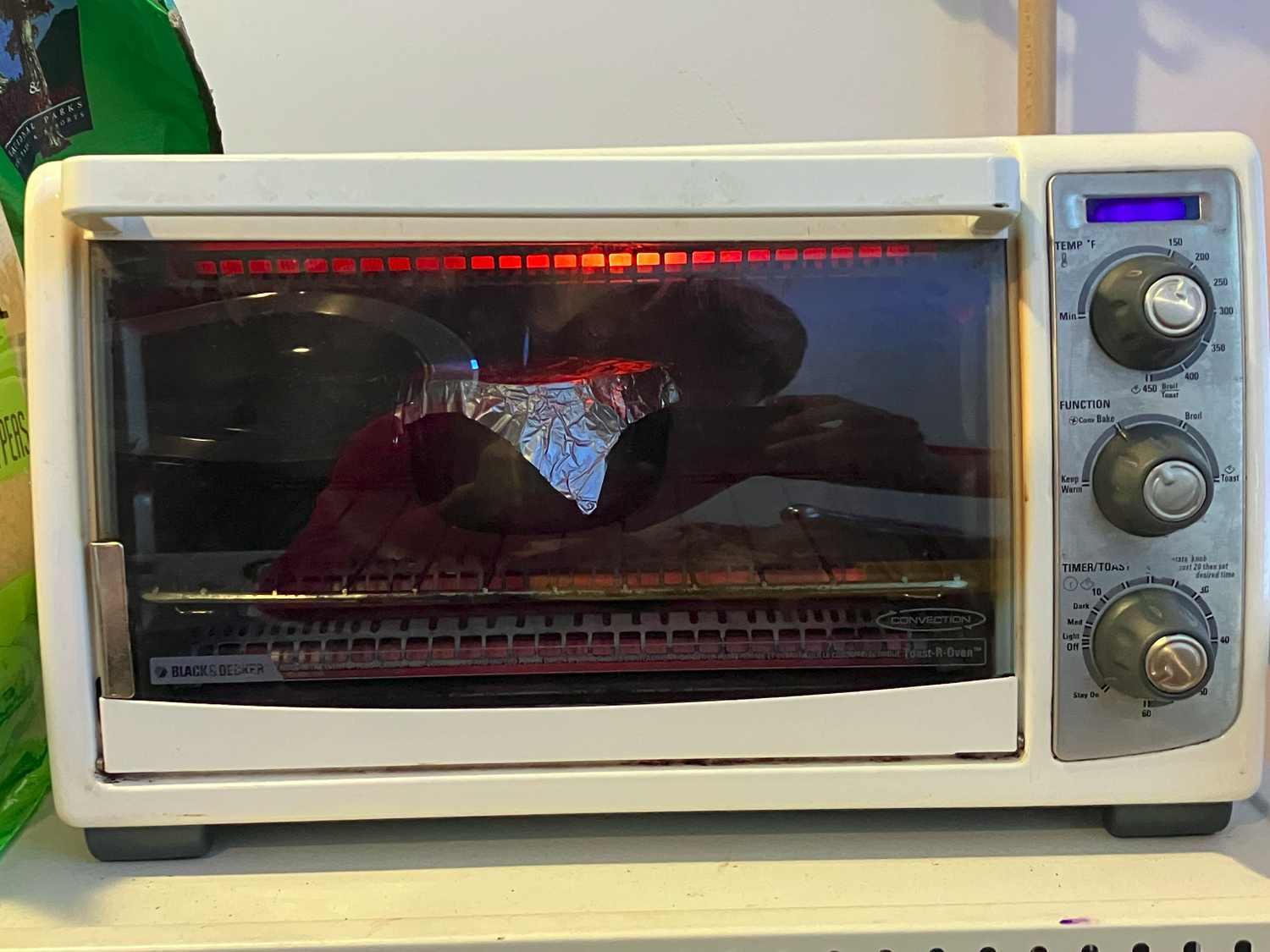

When a piece of dried clay is heated sufficiently, the water that is chemically bound to it is irreversibly driven off, and the clay particles bond covalently to each other. After this, the clay will no longer return to the plastic state if it gets wet. As it turns out, the temperature needed to dehydrate clays can be significantly lower than their firing temperature. According to this paper, it is between 400 °C and 600 °C for kaolins, but even lower for smectites — from 200 °C to 300 °C. Since the clay from my backyard is smectic, I was…

-

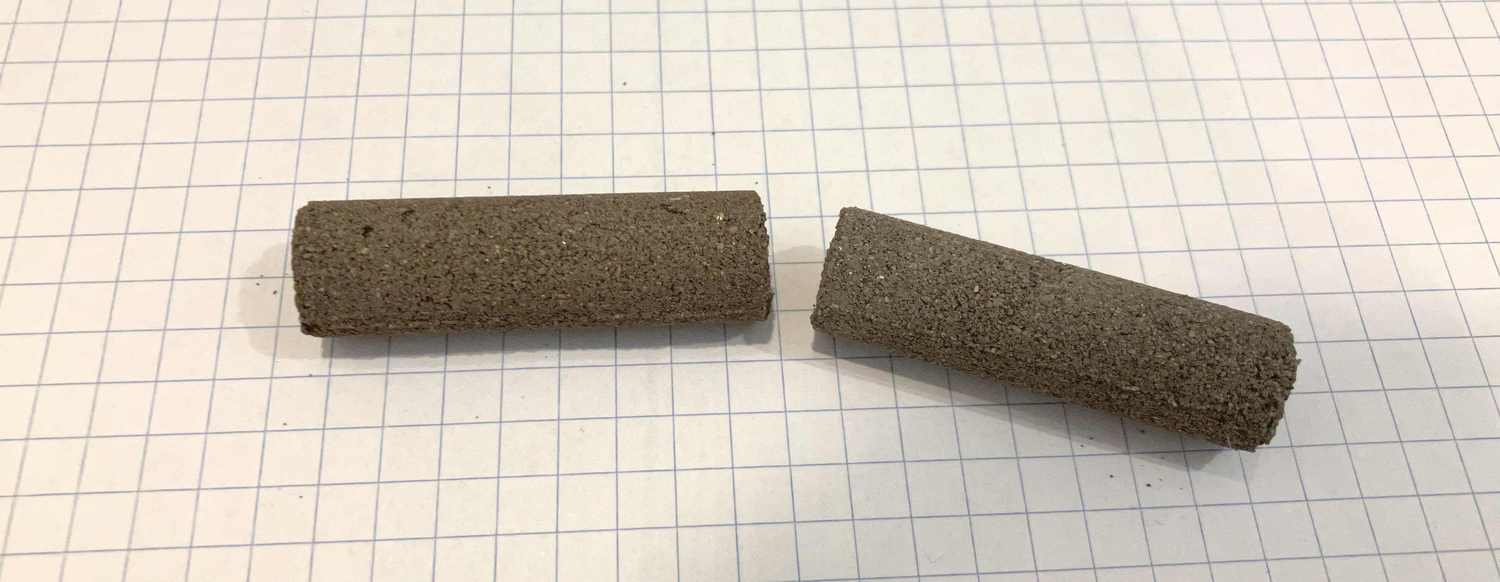

A problem I have struggled with in sand casting is mold tear-out. Even in patterns with generous draft angles, the sand very often gets torn out when the pattern is removed. Although charts of green sand mechanical properties versus moisture content, fineness, composition, etc. are available (for example in the US Navy’s Foundry Manual), the sand that I use is a bit different from industrial foundry sands in that it is much coarser, but has a higher proportion of binder, which is just clay soil from my backyard. I suspected that the binder may have been causing excessive pattern …

-

Introduction For the last year or so, I’ve been teaching myself sand casting. My metal of choice up until now has been zinc, because it is cheap and melts easily on a stove. I even built myself an electric stove out of an old air-fryer lid for melting zinc. So far, this has worked pretty well; the stove melts small amounts of zinc pretty quickly. But the stove doesn’t work too well when the weather is too windy, and zinc doesn’t have great mechanical properties: it’s brittle, weak, and dense. Wanting to melt other metals like aluminium and copper alloys…

-

One of the greatest advantages of AC power over DC is the ability to change its voltage by way of a transformer. However, transformers are bulky and expensive, especially variable transformers that allow household AC voltage to be lowered to throttle various electronic devices. But you can cheat: instead of varying the voltage, you can switch the power on and off to “chop off” part of each AC half-wave, effectively varying the voltage (though the output is not perfectly sinusoidal), with results that are good enough for many applications. Theory I found this very helpful article describing most of the…

-

Sand-cast parts commonly have internal geometries (ex. holes) that are produced with cores, internal molds made of bonded sand that are inserted into the main mold. The Theory I found an excellent book of practical sand casting information in the 1958 US Navy Foundry Manual. Cores are usually only supported by the mold at a few points, so they must be quite strong to withstand their own weight, as well as the buoyant forces produced when they are submerged in molten metal. For this reason they are made of a bonded sand different from normal molding sand. Typically, oil is…

-

I picked up a broken blender from a neighbor, hoping to fix it and use it for my own projects. The blender is powered by a 1500 W universal motor, whose speed is controlled by a TRIAC. A safety switch prevents the motor from running, even if it receives power from the mainboard, unless a blender bowl is put on with its lid in place. It also shorts out the motor when the bowl is removed, possibly as a safety feature to brake the motor if the bowl is suddenly removed rather than let it coast to a stop. A…

-

In a recent science fair project, I used a drill press as a press for strength testing. Drill presses are designed to exert fairly high forces while keeping the spindle perfectly straight. Pretty much all drill presses also have some provision to measure downwards travel, allowing the measurement of strain. Additionally, the self-holding Jacobs taper used to mount chucks can be used to mount 3D-printed test fixtures. This all makes drill presses a good choice for a DIY compressive or flexural strength-testing machine that you may already have at home. Unfortunately, since the Jacobs taper will release if you …

-

In this blog post, I detailed several ways of using backyard clay. The method that produced the best results was levigation, in which clay was suspended in water while impurities floated to the top or settled out. The clay-water was poured off and allowed to settle for a long time, after which the water was poured off from the settled clay. My mistake was severely underestimating the amount of clay that can be suspended in water. I initially thought that it worked something like the dissolution of ionic compounds, where clay particles go into suspension until the water can hold…