Introduction

Lately, when not crushed under the tedium of self-studying two AP exams, I’ve been trying to refine the clay soil from my backyard into clay. A post about that is coming. This post is about an interesting effect I noticed today as I test-fired pieces of clay.

Basically, clays often contain iron oxides (compounds containing different ratios of iron and oxygen with distinct properties) as an impurity, which gives them their color. Depending on whether the kiln’s atmosphere is oxidizing or reducing, these oxides can be transformed into one form or another during firing, changing the surface color of the pottery.

What I Did

After separating a small amount of clay from the soil through the “wet clay method” (look it up), I made a small ball about 20 mm in diameter and left it to dry. I also removed a 20 mm diameter, 1.5 mm thick “chip” of dried clay and set it aside.

I set the chip of clay on a heat-resistant base and used a blowtorch to heat it to cherry-red on both sides. Amazingly, it didn’t crack. The fired chip had its edges slightly vitrified from the high temperatures, but its faces were porous.

Then, I took the ball of clay and fired it inside a tin-can stove (a soup can with big holes drilled at the bottom and a fire grate made of wire mesh) with a similar technique to pit-firing:

- First, some wood was put in the stove and used to gently warm the ball, driving off any moisture.

- The wood was allowed to burn down to coals, then the ball was put on them and more wood was piled on top.

- The ball was removed after all the wood had burned down.

Results

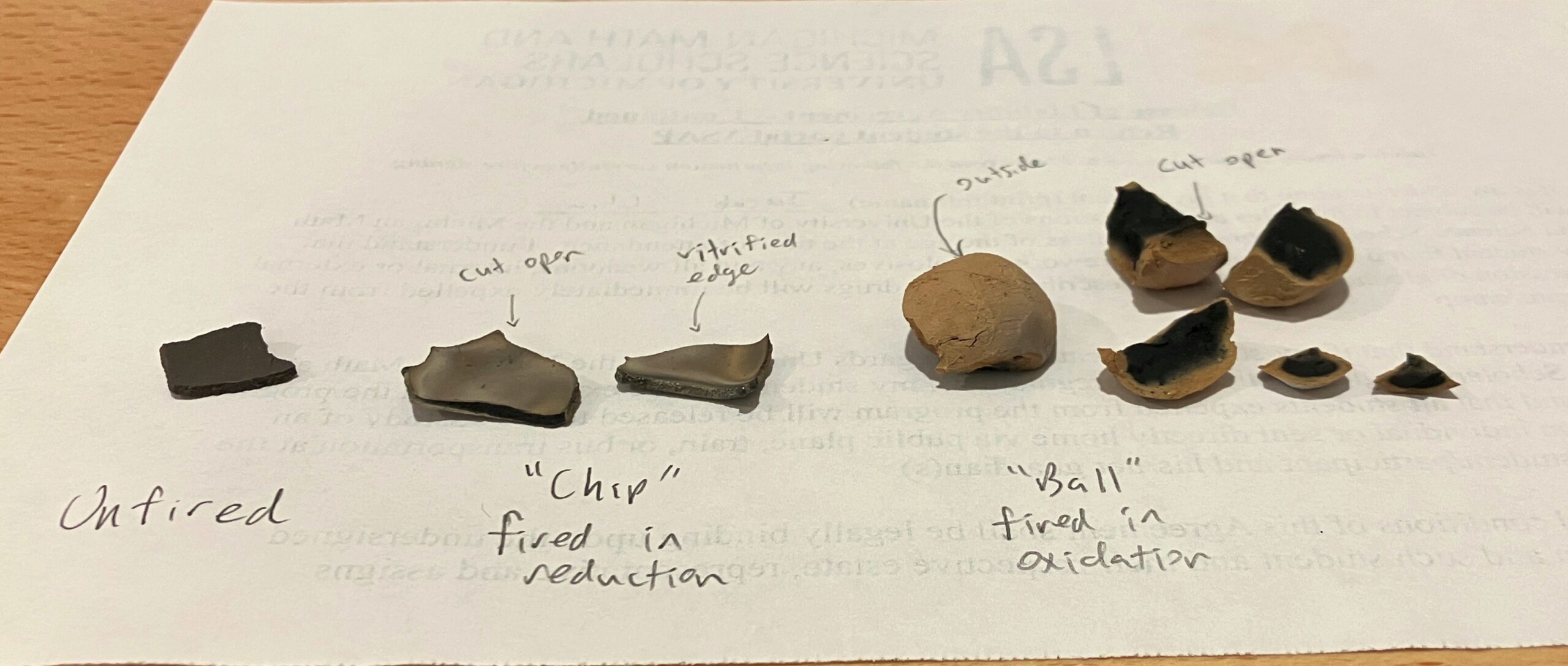

The featured image displays the results, and I think they’re pretty interesting, if not unexpected:

- The unfired clay was gray-brown in color. It was not magnetic.

- The clay chip, being fired in the reducing flame of the blowtorch, was light gray on the outside and black on the inside. It was very slightly ferromagnetic.

- The ball, fired in the oxidizing tin-can stove, was tan on the outside. Breaking it apart, the tan zone extended about 1 mm into the ball (farther where there were cracks) and the inside was black. It was not magnetic.

According to this site, iron oxide glazes become runny when fired in a reducing atmosphere, which matches the vitrification I saw on the edges of the chip, though the specific oxide is not mentioned. The black color on the inside probably comes from hematite, (the alpha phase of iron(III) oxide), iron(II) oxide, or unburned carbon in the clay due to the low firing temperature.

The ball’s tan color might be from β-Fe2O3 (the beta phase of iron(III) oxide), which is nonmagnetic, while the black color on the inside is probably also hematite, iron(II) oxide, or carbon.

One response to “Iron Oxide(s)!”

[…] As mentioned in a previous blog post, I tried using a blowtorch to fire the clay in reduction, and then a tin-can stove to fire in oxidation. This resulted in very different colors of clay and you can read about it here. […]